Md. Salman Rabbe Chy, Ragib Mahbub, Md Kowsar Alam ,Engr. Md. Abu Sayed

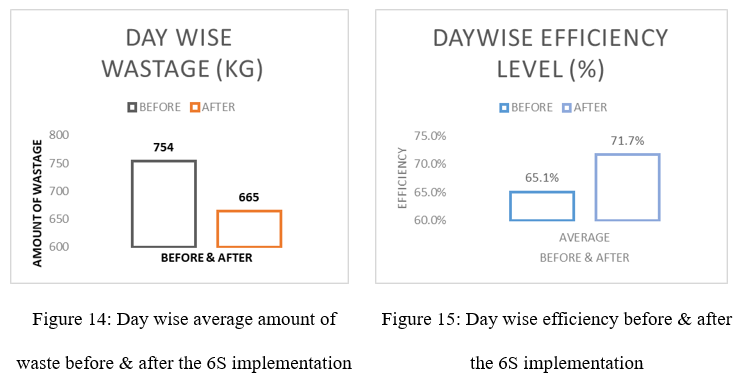

Enhancing Operational Efficiency and Sustainability: A Case Study on 6S Implementation in a Jute Spinning Facility

Md. Mehedi Hasan Niloy, Shoaib Islam Zico, Rafid Ahmed Chowdhury, Syed Redwanul Islam, Mohammad Iqbal, Elias Khalil

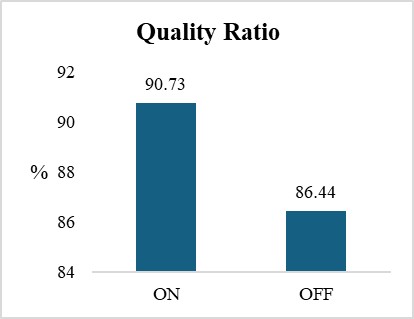

The Influence of Humidity Control on Jute Yarn Quality: A Path Toward Sustainability

Md Mehedi Hasan Niloy, Shoaib Islam Zico, Rafid Ahmed Chowdhury, Mahmudul Hasan Perves, Elias Khalil

Repetitive Upcycling of Waste Flax Fibre: A Circular Economy and Sustainability Approach in Yarn Manufacturing

Khen Maung, Mohammad Ali, Md. Musa Miah

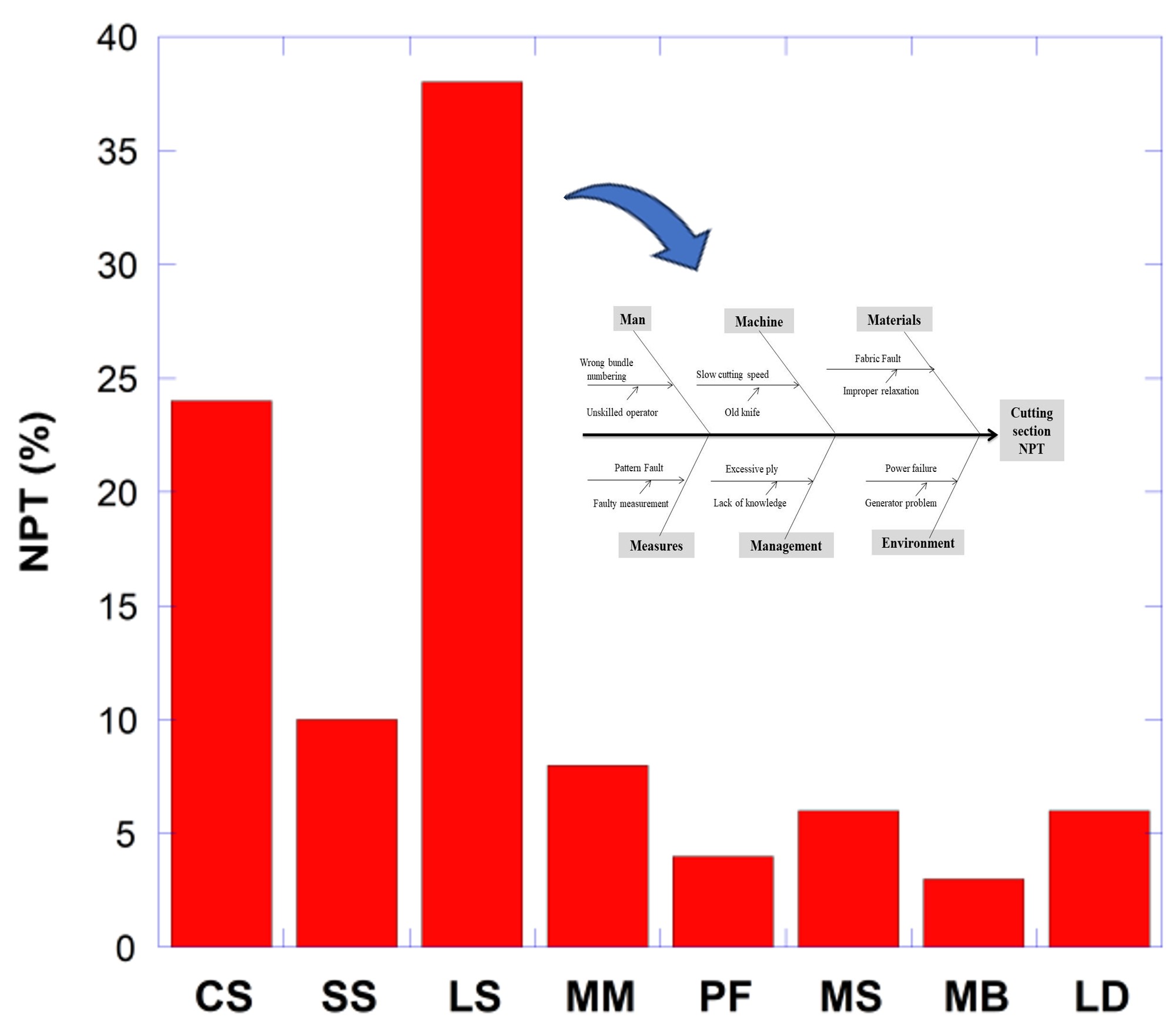

Reduction of Non-Productive Time in Apparel Manufacturing: A Garment Factory Case

Rimsa Taimy, Shafiullah Khan

Repetitive Upcycling of Waste Flax Fibre: A Circular Economy and Sustainability Approach in Yarn Manufacturing

Khen Maung, Mohammad Ali, Md. Musa Miah

Reduction of Non-Productive Time in Apparel Manufacturing: A Garment Factory Case

Rimsa Taimy, Shafiullah Khan

Enhancing Operational Efficiency and Sustainability: A Case Study on 6S Implementation in a Jute Spinning Facility

Md. Mehedi Hasan Niloy, Shoaib Islam Zico, Rafid Ahmed Chowdhury, Syed Redwanul Islam, Mohammad Iqbal, Elias Khalil

The Influence of Humidity Control on Jute Yarn Quality: A Path Toward Sustainability

Md Mehedi Hasan Niloy, Shoaib Islam Zico, Rafid Ahmed Chowdhury, Mahmudul Hasan Perves, Elias Khalil

Sustainable Textiles from Agro-Waste: Development and Performance Evaluation of Pineapple Leaf Fiber (PALF) Blended Yarns and 100% Cotton

Md. Salman Rabbe Chy, Ragib Mahbub, Md Kowsar Alam ,Engr. Md. Abu Sayed